Black pipe nipples are threaded iron/steel pipe nipples forged from high-quality carbon steel pipes after coating or sandblasting. Black steel pipe nipples are sandblasted or coated with anti-corrosion coating for increasing the corrosion resistance of the steel pipe nipples and prolong the service life. Hebei Sanvo is a professional carbon steel nipple manufacturer and supplier in China and customizes carbon steel and stainless steel pipe nipples. Among them, the black pipe nipples include seamless pipe nipple, welded pipe nipple, TOE pipe nipple/welding nipple, TBE pipe nipple/barrel nipple, close nipple/running nipple, and shoulder nipple.

This guide answers all the questions you have about black pipe nipples. If you have been looking for information about black steel pipe nipples, look no further.

You will find direct and detailed answers to common questions about black iron pipe nipples.

Without further ado, here we go:

Black pipe nipples of carbon steel are ungalvanized and have a dark, scaly iron oxide coating on their surface. SANVO black carbon steel pipe nipples are either oiled or sandblasted to protect their black surface from corrosion, making them suitable for applications that do not require galvanized steel.

Nominal Diameter: The nominal diameter of black steel pipe fittings typically ranges from small sizes (such as 1/8 inch) to large sizes (such as 6 inches), with a specific choice depending on the piping system requirements.

Standard lengths usually range from 1 to 1/2 inches of black fittings, and more sizes can be available.

SANVO is a good stainless and carbon steel nipple manufacturer, supplier, wholesaler, exporter, factory, and company in China, and supplies standard threaded steel pipe nipples, including ASTM A733, DIN2982, BS EN10241 standard steel pipe nipple, etc.

ASTM A733: A standard applicable to the American market, covering the dimensions, manufacturing requirements, and quality standards for threaded steel pipe joints.

(ASTM A733 Standard Black Iron Pipe Nipple Sizes/Dimensions)

(ASTM A733 Standard Black Iron Pipe Nipple Sizes/Dimensions)

DIN 2440/BS1387: This standard applies to black steel pipe joints in piping systems with higher wall thickness and pressure.

(DIN2440/BS1387 Standard Black Iron Pipe Nipple Sizes/Dimensions)

(DIN2440/BS1387 Standard Black Iron Pipe Nipple Sizes/Dimensions)

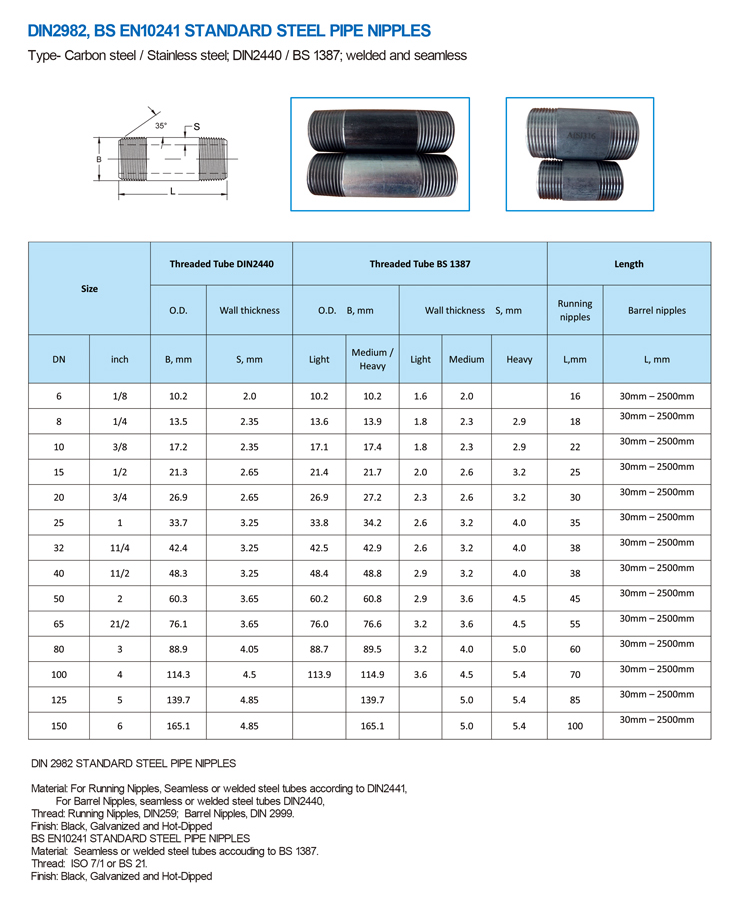

DIN 2982: A German standard for threaded fittings production, ensuring broad applicability in international markets.

BS EN10241: A British standard for carbon steel threaded fittings, widely used in the European market.

(DIN2982/BS EN10241 Standard Black Iron Pipe Nipple)

(DIN2982/BS EN10241 Standard Black Iron Pipe Nipple)

NPT (National Pipe Thread): An American standard thread suitable for fittings in the United States and some international markets.

BSP (British Standard Pipe): A British standard thread commonly used in European and Asian markets.

Tapered and straight threads are specific application contexts that determine the choice of thread form. Tapered threads are typically used for high-pressure pipeline connections, while straight threads are mostly for low-pressure or non-fluid pipeline systems.

Wall Thickness (Sch 40, Sch 80): Black steel pipe fittings typically use standard wall thickness (Schedule 40) or thicker versions (Schedule 80) to meet different pressure requirements.

Common materials include carbon steel, available in uncoated (black) or oil-coated/sandblasted finishes to enhance corrosion resistance based on specific requirements.

Determining what size pipes you need for your project can be confusing. Many people assume pipe size is the outer diameter of the pipe—but “pipe size” actually refers to what is called “nominal diameter.”

Fittings can be just as confusing. Their inside diameters must be large enough to fit over the pipe's outside diameter. A half-inch steel elbow, for example, has an outside diameter of about 1-1/4 inches.

The easiest way to find what nominal pipe size you need is to use follow these steps.

For Black Pipe Nipple:

Wrap a string around the pipe

Mark the point where the string touches together

Use a ruler or measuring tape to find the length between the tip of the string and the mark you made (circumference)

Divide the circumference by 3.14159

Nominal Diameter Conversion Chart (All Measurements in Inches)

The primary differences between black nipples and galvanized nipples lie in their materials, coatings, and applications:

Black Nipples: Made from uncoated carbon steel. They have a plain finish without any protective coating.

Galvanized nipples are made from carbon steel and coated with a layer of zinc through galvanization.

Black nipples are more susceptible to rust and corrosion because they lack a protective coating. They are suitable for dry indoor environments.

Galvanized nipples are Highly corrosion resistant due to the zinc coating, making them suitable for outdoor or humid environments where moisture is present.

Black Nipples are suitable for low-pressure gas and oil lines. They are fit for places where they won't get wet.

Galvanized Nipples: Ideal for water plumbing applications, especially outside or wet environments and heating systems.

Black Nipples characteristically have a dark, matte finish.

Galvanized Nipples have a shiny, metallic finish due to the zinc coating.

In summary, black nipples are suitable for specific applications with minimal exposure to moisture. Galvanized nipples get a lot of attention in building trades and water lines because of their strength and ability to resist rust in wet conditions.

Our black pipe nipples can be customized according to drawings, samples, or special requirements of customers, and send samples for free. So, you can choose Hebei Sanvo Pipes And Fittings Co., Ltd. to purchase black pipe nipples.