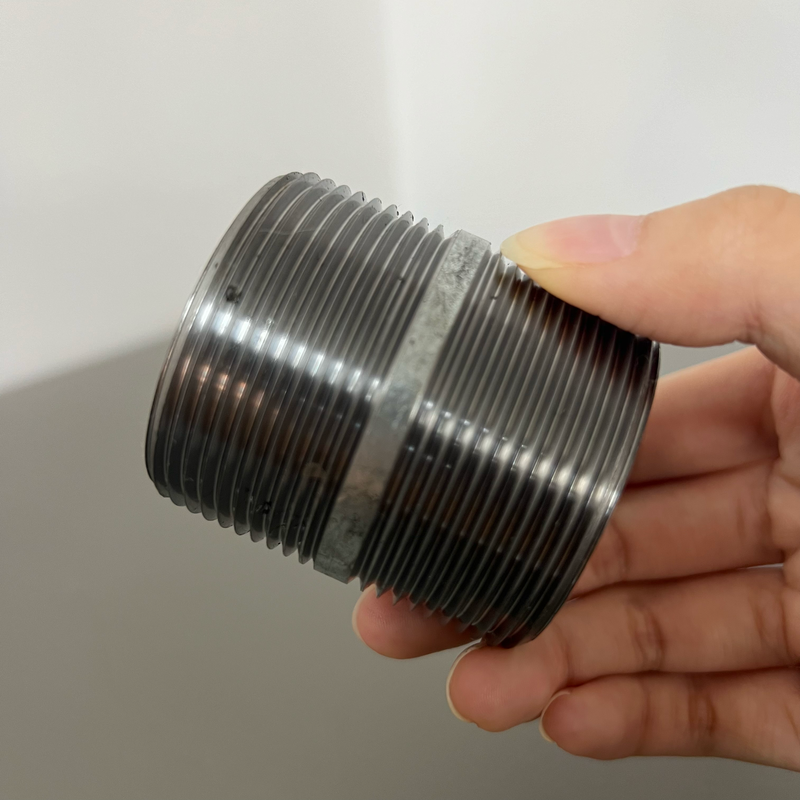

China Pipe Nipple Suppliers Wholesales BS EN10241 Standard Threaded Steel Pipe Nipple Shoulder Nipple Plumbing 2 Inch Galvanized Shoulder Nipple With A Very Short Unthreaded Space Between The Threads. High-quality connectors available at wholesale prices include shoulder nipples specifically for plumbing applications. The galvanized shoulder nipple has a shortly unthreaded part between the threads, ensuring a reliable and secure connection in plumbing installations, meeting the demands of both commercial and residential projects.

Shoulder nipples are longer than a close nipple and include a concise unthreaded space between the threads. The unthreaded space is not large enough to fit a pipe wrench. When two female fittings are screwed onto either end, a small piece of the nipple will remain exposed. A shoulder nipple is the first length of the nipple, available up from a close nipple.

This galvanized shoulder nipple plumbing is designed for potable water applications. It is pressure tested for reliability and available in various sizes to fit residential and light commercial water applications. This pipe nipple is rated at 230 PSI at 400 degrees F.

Galvanized pipe nipples are male, NPT threaded at both ends connect easily to fittings, and are intended to fight rust and corrosion. They can be used in low-pressure plumbing applications including air, water, oil, natural gas, and steam. All these pipe nipples are certified for use with potable water.

Anti-corrosion coating: A zinc galvanized coating protects against air, moisture, and other corrosive substances, making it suitable for wet and corrosive environments.

Economical: Cheaper and anti-corrosion than stainless steel, galvanized pipes with long service life and low maintenance cost, is a highly cost-effective choice.

Strength: A galvanized nipple has mechanical properties and enhances its durability with the galvanized coating at the same time.

Beautiful appearance: Silver-white surface, smooth and suitable for outdoor application.

Process and weld easily: Galvanized steel that can be cut, bent, and welded to manufacture any shape, suitable for many industrial needs.

Antiwear: Galvanized coating has high hardness to prevent a degree of damage.

Galvanized steel provides exceptional resistance to rust and corrosion, significantly extending the lifespan of the nipple. It is an environmentally friendly material and suitable for liquid environments.

Galvanized shoulder nipples are highly adaptable and used in various applications. Their ability to handle multiple fluids is an ideal option.

These nipples can withstand significant pressure and are suitable for high-temperature and high-pressure applications.

Durable, the galvanized shoulder nipples can be long-term used because the galvanized materials can offer a long lifetime and stability and do not need to change frequently.

Thread Standards: NPT, BSPT, BSP, DIN.

Length: 1 inch to 12 inches, and we can customize sizes according to customer needs.

Construction and engineering

Construction and engineering

Oil and gas project

Chemical and medicine

Machine and equipment install

Ship and marine engineering

Regular inspections of the piping system for any signs of wear, corrosion, or leaks can facilitate early detection and prevent issues down the line.

Keep the nipples and surroundings clean to avoid the buildup of debris that could lead to blockages or damage over time. Use a cloth to wipe down the areas around the fittings as necessary.

1 inch x 2 inch galvanized shoulder nipple made of hot-dipped galvanized steel;

Galvanizing can increase the corrosion resistance of steel pipe nipples and extend the service life;

Galvanized nipple is certified to NSF 61 and the lead-free law;

The galvanized steel nipple is widely used and can be used for pipeline transportation of general low-pressure fluids such as water transportation, gas, oil, etc;

Always check your local plumbing and gas codes before starting any piping projects.

The use of galvanized steel is not only beneficial for durability but also for environmental sustainability. The galvanization process helps to minimize the risk of rust and corrosion, reducing the need for frequent replacements and thus lowering waste.

Additionally, galvanized nipples can be recyclable at the end of their service life, contributing to a more sustainable approach in plumbing and construction.